Limestone is the main raw material for the manufacture of cement, lime and calcium carbide, and is an indispensable flux limestone in the metallurgical industry. After ultra-fine grinding, high-quality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other products.

After the research of Xinxiang Great Wall Machinery Industry Waste Residue Powder Research Center, CHAENG can provide 200,000-1,500,000t/a nickel slag production line project.

Aiming at the characteristics of steel slag, CHAENG proposes a 200,000 to 1.5 million tons per year turnkey service plan for the comprehensive utilization of steel slag, which uses vertical roller mills as the main grinding equipment.

The whole system of cement grinding station mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is composed of cement mill, OSEPA high-efficiency separator, elevator, packing machine and so on. In order to meet the customers' requirements on different granularity of auxiliary materials, it can be equipped with high-efficiency hammer crusher for optimal combination and classification.

CHAENG is a cement industry equipment manufacturer with more than 60 years of experience, can provide not only slag grinding equipment, but also complete turnkey solutions for grinding blast furnace slag (GGBS) production.

CHAENG can undertake the 200-1500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging --- "turnkey” service with production capacity and standard achieved.

The cement grinding unit produced by Xinxiang Great Wall Machinery integrates drying, grinding, powder classification, dust removal, and cement packaging. We can provide cement grinding units with different capacities and different equipment.

CHAENG has the ability to build 300t/d-3000t/d cement production lines independently and has extensive experience in the design and construction, building many cement plants.

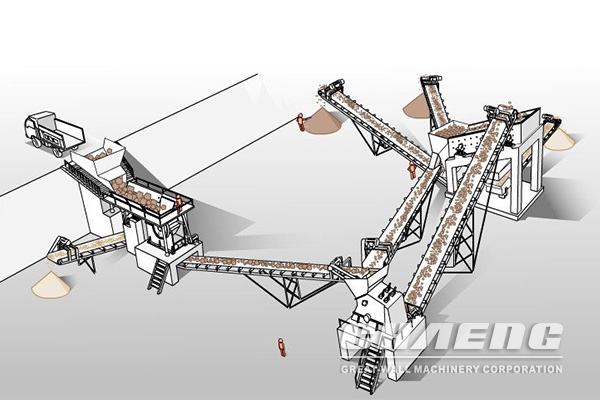

Crushing plant includes vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc. The designed capacity is from 50t/h to 500t/h.